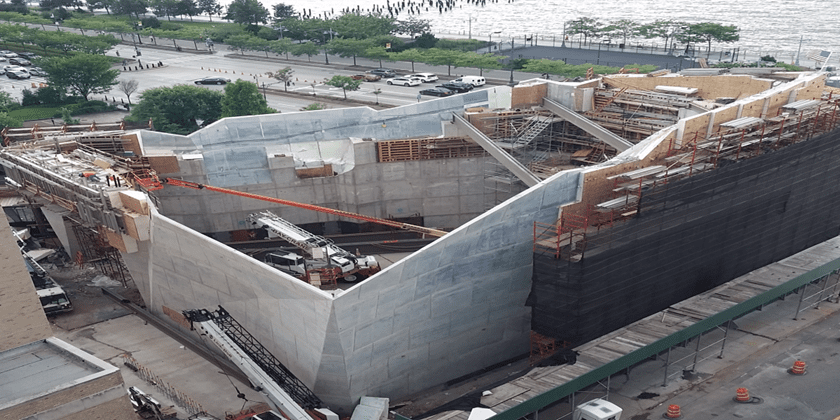

EDC’s Reinforced Concrete Products for Waterline Square Buildings 1,3 & 4.

The transformation of an old Penn Central rail yard into the Riverside Center master-planned community of upscale, residential high-rises has taken two decades. EDC was pleased to assist with the final trio of buildings.

The structures, named Waterline Square, broke ground in 2015 and were built simultaneously. Their completion is scheduled for 2019.

EDC was selected to provide solutions for the cast in place concrete shoring and formwork requirements with its extensive inventory of frame shoring, post shores, Sonotubes and more. EDC also provided the Screen Saver perimeter protection system on building 3.

Inside, the condos and rental units have wide-open spaces free of interior columns. They also feature high-ceilings and floor-to-ceiling windows.

Have a high-rise construction project for which you need high-quality supplies and expertise?

With our extensive rental inventory and our in-house ability to manufacture customized products, we are your one-stop shop for all reinforced concrete supplies. Fill out our contact form or give us a call at 201-641-2880 to discuss your project with one of our experts.