Threaded Mechanical Splicing Systems

- Provide reliability & consistency of maintaining load path continuity of the structural reinforcement, independent of the condition or existence of the concrete.

- Supplied in any length, and fabricated to your requirements.

- American made ASTM A615 reinforcing steel, mill certified.

- Manufactured to exceed 125% x specified yield strength fy Grade 60.

- Splice systems are compliant with ACl 318 specifications & AASHTO standard specifications for highways & bridges.

- All threaded couplers are made from material satisfying ASTM A-108.

- EDC threaded mechanical splicing systems are supplied as 2-piece systems, which include a male splice bar and a female setting bar with a coupler attached. Ready to use in sizes #4 through #11.

Benefits:

- Mechanical connections offer greater structural integrity.

- Mechanical splices offer strength & toughness during man-made, seismic or other natural events.

- Mechanical splicing systems eliminate projecting rebars, protect the safety of workers, reduce the cost of rebar and reduce bar congestion.

ASTM A-615 Grade 60 Rebar

A615 grade 60 reinforcing bars are the most widely used type and grade of reinforcing steel.

A615 rebar is available is available in a wide range of sizes. See chart for available sizes and dimensions.

| Bar Size Designation | Weight (lbs. per lineal ft.) | Nominal Diameter | Cross Sectional Area (sq. inches) | Minimum Loads (lbs.) |

|

| Py | 1.25 Py | ||||

| #4 | 0.668 | .500 | .20 | 12,000 | 15,000 |

| #5 | 1.043 | .625 | .31 | 18,600 | 23,250 |

| #6 | 1.502 | .750 | .44 | 26,400 | 33,000 |

| #7 | 2.044 | .875 | .60 | 36,000 | 45,000 |

| #8 | 2.670 | 1.000 | .79 | 47,400 | 59,250 |

| #9 | 3.400 | 1.125 | 1.00 | 60,000 | 75,000 |

| #10 | 4.303 | 1.250 | 1.27 | 76,200 | 95,250 |

| #11 | 5.313 | 1.410 | 1.56 | 93,600 | 117,000 |

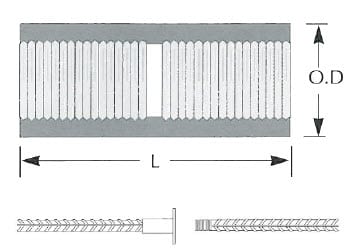

Standard Coupler

EDC couplers are designed to eliminate protruding rebar and extend rebar without damaging formwork. Standard couplers have an internal positive stop to ensure proper thread engagement. Couplers may be supplied with or without a flange.

See chart for available sizes and dimensions.

| Coupler Size | Thread Size | Coupler Weight (lbs.) | Coupler Length (inches) | Coupler O.D. (inches) | Flange Size (optional) |

|---|---|---|---|---|---|

| #4 | 1/2" - 13NC | 0.23 | 2" | 7/8" | 2"x2" |

| #5 | 5/8" - 11NC | 0.28 | 2 1/4" | 1" | 2"x2" |

| #6 | 3/4"- 10NC | 0.39 | 2 3/8' | 1 1/8" | 2"x2" |

| #7 | 7/8"- 9NC | 0.55 | 2 3/4" | 1 1/4" | 2"x2" |

| #8 | 1"- 8NC | 0.99 | 3 3/8" | 1 1/2" | 2"x2" |

| #9 | 1 1/8"-7NC | 1.66 | 3 7/8" | 1 5/8" | 2 1/2"x2 1/2" |

| #10 | 1 1/4"- 7NC | 2.57 | 4 3/8" | 2" | 2 1/2"x2 1/2" |

| #11 | 1 3/8"- 6NC | 2.60 | 4 7/8" | 2" | 2 1/2"x2 1/2" |

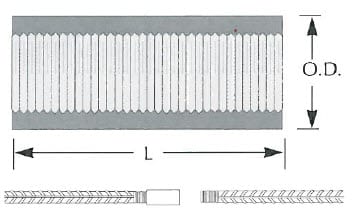

Positional Coupler

EDC positional couplers are especially convenient when rebar cannot be rotated to engage threads. Positional couplers are tapped through to allow full positioning on one bar, then rotation back on to the other bar.

See chart for available sizes and dimensions.

| Coupler Size | Thread Size | Coupler Weight (lbs.) | Coupler Length (inches) | Coupler O.D. (inches) |

|---|---|---|---|---|

| #4 | 1/2"- 13NC | 0.20 | 1 3/4" | 7/8" |

| #5 | 5/8"- 11NC | 0.25 | 2" | 1" |

| #6 | 3/4"- 10NC | 0.35 | 2 1/8" | 1 1/8" |

| #7 | 7/8"- 9NC | 0.50 | 2 1/2" | 1 1/4" |

| #8 | 1"- 8NC | 0.90 | 3" | 1 1/2" |

| #9 | 1 1/8"- 7NC | 1.50 | 3 1/2" | 1 5/8" |

| #10 | 1 1/4"- 7NC | 2.35 | 4" | 2" |

| #11 | 1 3/8"- 6NC | 2.40 | 4 1/2" | 2" |

If you have any questions about the suitability of A615 rebar for your application, please give us at call at 1-201-641-2880 and one of our experts will assist you.